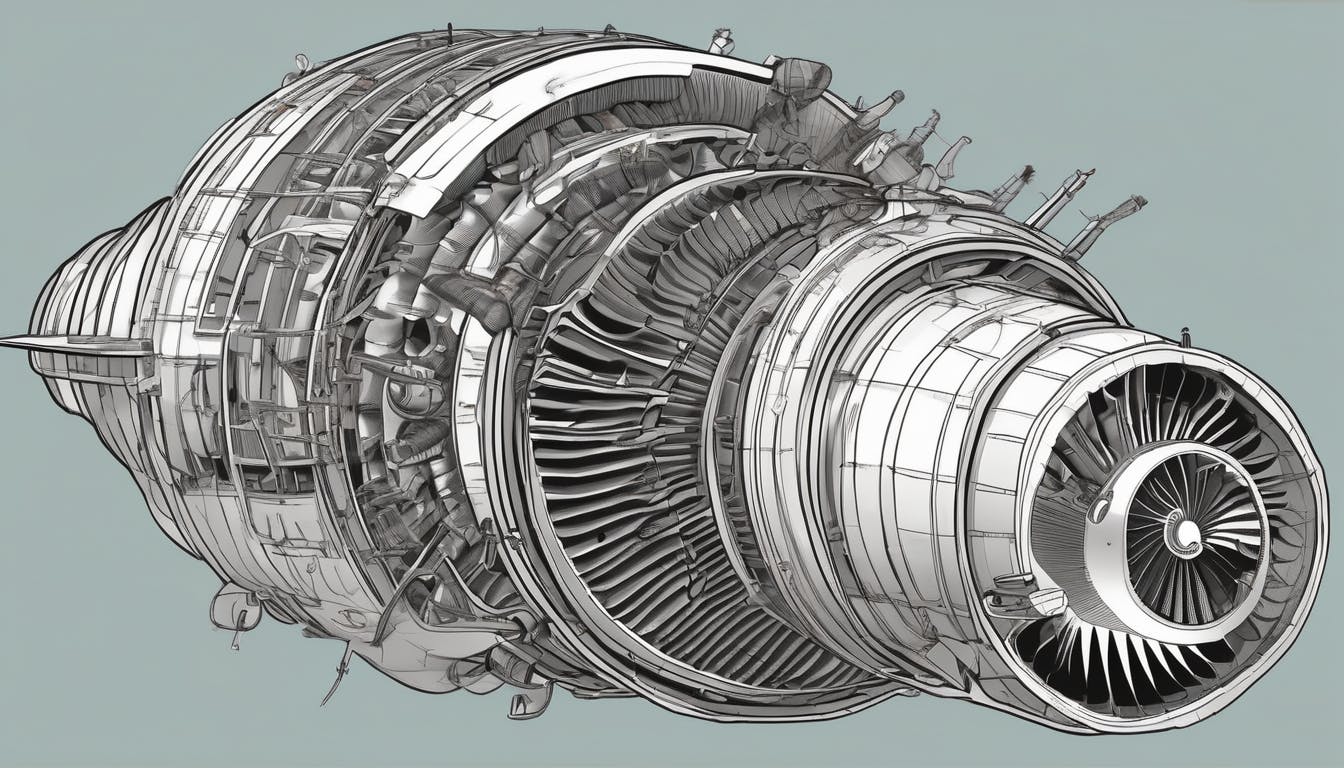

Jet engines are the powerhouses that propel modern aircraft through the skies at incredible speeds. Understanding how these complex machines work is essential for anyone interested in aviation or engineering. In this blog post, we’ll explore the inner workings of jet engines, focusing on the turbofan design that has become the standard in today’s aircraft.

Turbofan Engine: The Modern Jet Propulsion Technology

Turbofan engines are the most common type of jet engine used in modern aircraft. They offer several advantages over the older turbojet design, including improved fuel efficiency and reduced noise levels. The key difference between a turbofan and a turbojet is the addition of a large fan at the front of the engine.

Turbofan engines come in two main varieties:

High bypass engines, which are used in commercial airliners and move large quantities of air at slower speeds for better fuel efficiency.

Low bypass engines, which are more compact and have higher power-to-weight ratios, making them ideal for military fighter aircraft.

Key Components of a Jet Engine

To understand how a jet engine works, it’s important to know the key components and their functions:

Compressor: The Powerhouse of Jet Engines

The compressor is responsible for compressing the incoming air, increasing its pressure and temperature. This process is essential for efficient combustion. The compressor consists of low-pressure and high-pressure stages, each with a spinning rotor and stationary stator vanes.

Combustor: Where the Magic Happens

In the combustor, the compressed air is mixed with fuel and ignited, creating a high-energy gas stream. Most modern jet engines use an annular combustor design, which is shaped like a ring. Fuel injectors and igniter plugs ensure an even mixture and continuous combustion.

Turbine: Harnessing the Power of Exhaust Gases

The turbine section is powered by the hot exhaust gases from the combustor. As the gases pass through the turbine blades, they cause them to spin, which in turn powers the fan and compressor. Turbine fins are subjected to extreme temperatures, so cooling techniques and special coatings are used to protect them.

Exhaust Cone: Mixing and Accelerating Exhaust Streams

The exhaust cone is designed to mix and accelerate the exhaust streams from the core and bypass sections of the engine. In high bypass engines, the exhaust cone also helps reduce noise by surrounding the fast-moving core exhaust with slower-moving bypass air.

Afterburner: Boosting Jet Engine Performance

Some high-performance jet engines, particularly those used in military aircraft, feature an afterburner. An afterburner injects additional fuel into the exhaust stream, creating a second stage of combustion. This provides a significant boost in thrust, but at the cost of increased fuel consumption. Afterburners are typically used in short bursts during takeoff, climbing, or combat maneuvers.

Jet Engine Efficiency and Noise Control

Jet engine manufacturers are continually working to improve efficiency and reduce noise. High bypass engines have greatly improved fuel efficiency and noise reduction in commercial aircraft. Innovative designs, materials, and manufacturing techniques are being developed to further enhance jet engine performance while minimizing their environmental impact.

FAQ (Frequently Asked Questions)

What is the difference between a turbofan and a turbojet engine?

The primary difference between a turbofan and a turbojet engine is the presence of a large fan at the front of a turbofan engine. This fan drives a significant portion of the engine’s airflow around the core, improving fuel efficiency and reducing noise compared to a turbojet.

How does a jet engine start?

Jet engines are started using a small motor or compressed air to spin the compressor. Once the compressor is spinning fast enough, fuel is introduced and ignited by the igniter plugs. The combustion process then becomes self-sustaining as long as fuel and air are supplied.

Why are turbine blades often made from advanced materials?

Turbine blades are subjected to extremely high temperatures and stresses during operation. Advanced materials, such as nickel-based superalloys and ceramic matrix composites, are used to withstand these harsh conditions and ensure the longevity of the turbine components.

How do jet engines contribute to aircraft noise reduction?

Modern high bypass turbofan engines reduce noise by surrounding the fast-moving core exhaust with a larger volume of slower-moving bypass air. This helps to muffle the noise generated by the engine. Additionally, advanced acoustic liners and noise-absorbing materials are used within the engine to further reduce noise levels.